UNL Senior Capstone Project: Kawasaki Robot for Educational Demonstrations

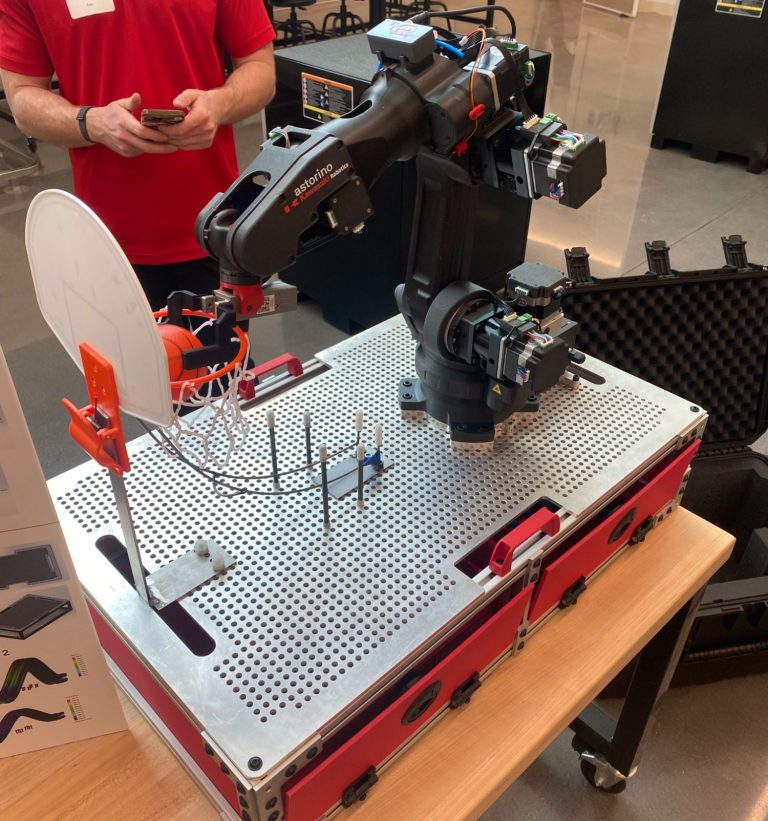

As Team Leader of my Senior Design Capstone Project for both semesters, we have developed a transportation system, designed an original robot operations base, and coded preset movements all for the Kawasaki Astorino Robot. This partnership was created to aid Kawasaki's mission to produce interest in their robotics division in students of all ages throughout Lincoln, Nebraska. These systems allow for the full exposure of Kawasaki's newest advanced training robot, ensuring it is safely delivered and operated to showcase its capabilities. The full results of the project are explored below!

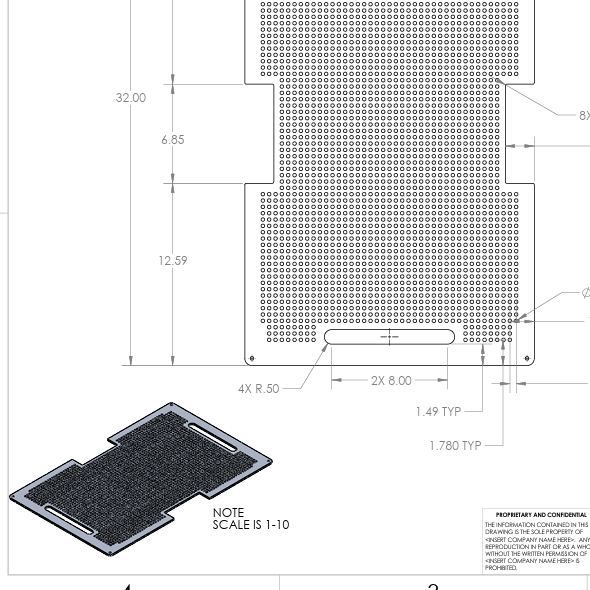

80/20 Base w/ Storage Compartments

We created the base for the robot out of 80/20 components, which allowed for a higher level of design opportunities due to the t-slots integrated into the aluminum bars. Not pictured are handles that will be attached to the top face of the 80/20 bars to aid easy transportation and movement. The two red panels on the left will have handles and hinges attached to create doors which will fold down for storage compartments. The compartments will be divided down the middle via a plastic divider. Inside both compartments various small items can be housed, such as extension cords, spare parts kits, tools to attach and detach items to the build plate, and more.

Build Plate

We created our own build plate that allows the Astorino robot to be placed anywhere in any 90 degree orientation. It also adds versatility when including components for the robot to interact with for any potential educational demonstration.

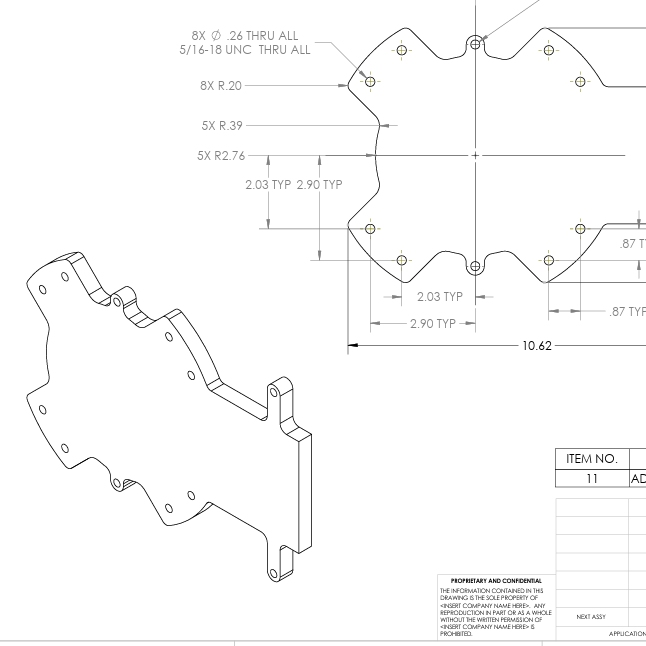

Adapter Plate

Since the Astorino's hole pattern didn't allow for a matching, seamless hole distribution in the build plate, an adapter plate was created to be the medium between the robot and build plate. Not catering the hole distribution in the build plate to the specific Astorino holes allowed for a more standardized build plate design.

Travel Case Foam Design:

Designed and Purchased through MyCaseBuilder.com

Teach Pendant

The skinny portion on the top left allows for the placement of the teach pendant, which is an external controller that aids in robot movement. Finger holes were added for ease of removal.

Extra Storage

The bottom left of the foam design allows carves space for various extra components, such as the emergency stop, and other power cords.

Seamless Fit

The Astorino robot and its various components will fit snug into the foam depression, as it's geometry was based off the packaging it came in.

Streamlined Setup

The foam design allows for the adapter plate to be left connected to the bottom of the robot, which simplifies the setup and takedown procedures.

Travel Case

Purchased through MyCaseBuilder.com

The travel case will contain the full foam design displayed above, which will house the Astorino robot and its additional components safely. It contains a full extendable handle and wheels that allow for simple "suitcase" type transportation.

Coded Demonstration

Our coded demonstration, which was displayed at the Senior Design Showcase, was the simple repeatable task of dunking a toy basketball into a hoop. After Kawasaki assisted in the creation of the ball return system, our team coded and programmed the cyclic robot motion. This was a wonderful way to expose ourselves to the Kawasaki programming language, and we hope that others can gain the same amount of learning and enjoyment that we have.

David Lynch

Aspiring Mechanical Engineer

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.